When operating high yield assets within a business, it is important to protect them to avoid unnecessary downtime or unpleasant surprises. One crucial approach to protecting these high yield assets is to provide reliable equipment and solutions. Protecting Assets with…

Admin

Preparing Control Valves for Winter With winter right around the corner, the team at Clarke Valve wants to make sure that our customers and their applications are prepared. Winterization is an important factor in properly maintaining outdoor valves and actuators,…

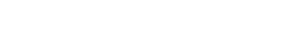

With the advent of Digital Twinning, operating companies no longer need to run the risk of introducing a flow element into their process without total confidence in its process and reliability performance. Clarke Valve, the exclusive manufacturer of the revolutionary…

Rawson/Industrial Controls Named Exclusive Multi-State Distributor for Clarke Valve Rawson/Industrial Controls, an ERIKS North America company, announced that it is the exclusive distributor for Clarke Valve products to oil and gas and other industrial companies in Pennsylvania, West Virginia, Texas,…

Clarke Valve, a Chevron Technology Ventures portfolio company, is excited to announce that the reliable, low-torque Dilating Disk™ Valve has passed the external leakage requirements of the API 607 fire test, per the Chevron Control Valve Standard, ICM-SU-5102-C.3. During this test,…

Lead Design Engineer Justin Mancovsky presented on behalf of Clarke Valve in the Technology Showcase at the SHALE INSIGHT™ 2019 Conference, discussing the Dilating Disk™ Valve and its ability to curb fugitive emissions by 97% compared to common control valves.

Clarke Valve, developer and manufacturer of the world’s most reliable, efficient and compact control valve, has reached yet another technical advancement, to add to its ever-expanding list of notable achievements. On April 7, 2020, Clarke Valve secured a U.S. Patent…

North Kingstown RI, March 31, 2020 – Clarke Valve (“Clarke”) today completed the sale of $10 million of Series C Preferred Stock to a group of investors led by YBA Kanoo Group (“Kanoo”). Mr. Ali Abdulla Kanoo, President of the…

Clarke Valve, a portfolio company of Saudi Aramco Energy Ventures, Chevron Technology Ventures, and OGCI Climate Investments, announced today that it has secured a CE Marking, following the successful completion of the certification guidelines outlined in PED Module H 2014/68/EU….

On July 25, 2019 the United States Naval Sea Systems Command (NAVSEA) published Detail Specification MIL-DTL-32632, which establishes the criteria for the design, materials, and functional capabilities of all “dilating disk” valves for flow control of Naval shipboard water, oil,…