ABOUT Clarke Valve

The Next Generation of Control Valves

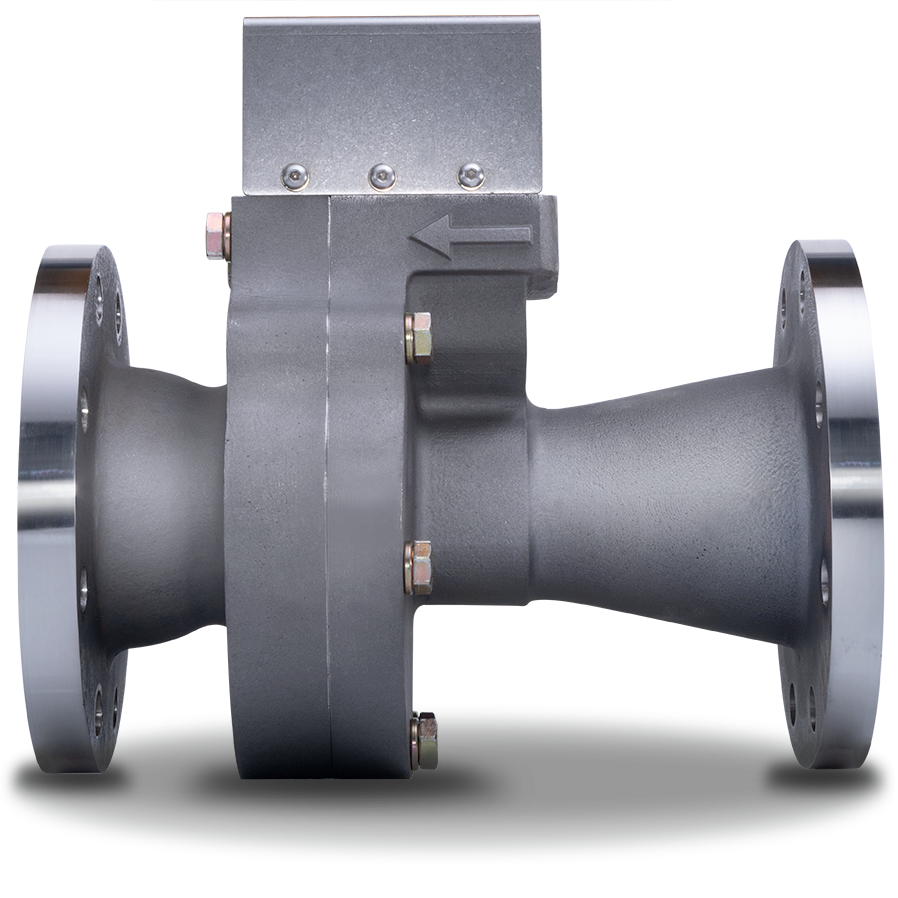

Clarke Valve is the exclusive manufacturer of the Dilating Disk™ Valve; an advanced technology quarter-turn valve characterized by its three interlocking petals that control the flow of process fluid. It is a torque-seated valve which employs PTFE or Metal to Metal sealing, and offers a patented series of stem seals that are API 641 and ISO 15848-1 certified to reduce fugitive emissions by 98%. In addition to conforming to a wide-ranging list of industry standards, the Dilating Disk™ Valve is safety integrity level 3 certified, with sizes ranging from 0.25” to 12” and pressure ratings from ASME Class 150 to 1500. With a customer base consisting of over 35 of the leading oil and gas companies in the world, Clarke Valve provides reliable, plug-and-play control valves that allow their customers and partners to meet environmental standards within a compact and low-weight design. To maintain the reliability of Clarke Valve’s manufacturing and operations, the Rhode Island, USA-based facility utilizes an extensive variety of cutting-edge digital design, development, and testing equipment.

Quality Policy

Clarke Valve is dedicated to providing the highest quality industrial valves to our customers, defect-free and on time. We are committed to satisfying all customer and applicable requirements and to the continual improvement of our business, products, processes, and quality management systems. All valves produced by Clarke Valve are designed, inspected, and tested in strict conformance to the applicable industrial valve standards and codes to ensure maximum product safety and reliability.

Mission Statement

Our mission is to continue to innovate and develop valves that customers, technicians, mechanics and engineers love to use.

Configure Your Own

Dilating Disk™ Valve Today!

NEWS + UPDATES

Kyle Daniels, CEO and Founder, Clarke Valve and inventor of the Dilating Disk™ Valve gives an insight into the technological shift and transition of valves manufacturing which is designed to regulate emissions and provide efficient processes in the oil & gas…

As operators in the oil & gas industry, it is vitally important to optimize the performance of control valves to maximize efficiency and profitability while maintaining safety and reliability. Usually, during a turnaround or maintenance, control valves need to be…

As 2022 winds to a close, it’s time for a look back at some of the most promising startups and the entrepreneurs leading them in Rhode Island over the past year. At Rhode Island Inno we covered a wide array…