This is the Clarke Valve Dilating Disk Valve. A completely reimagined, precision control valve that is light years ahead of any other control valve on the market today. The Dilating Disk series of valves deliver unparalleled efficiency and adaptability, putting them in a class of their own when it comes to efficiency, size, reliability and sustainability.

Easy Installation

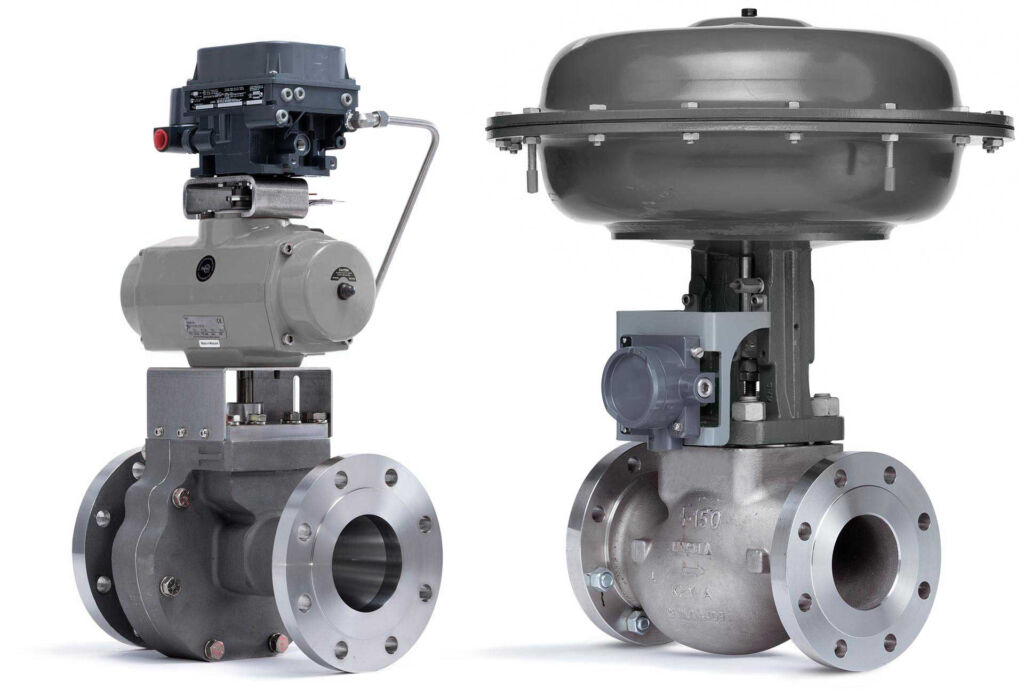

Exact face to face dimensions (ISA 75.08, ASME B16.10) as current globe valves, no pipe modifications required for installation. Uses manual, pneumatic, electric actuators.

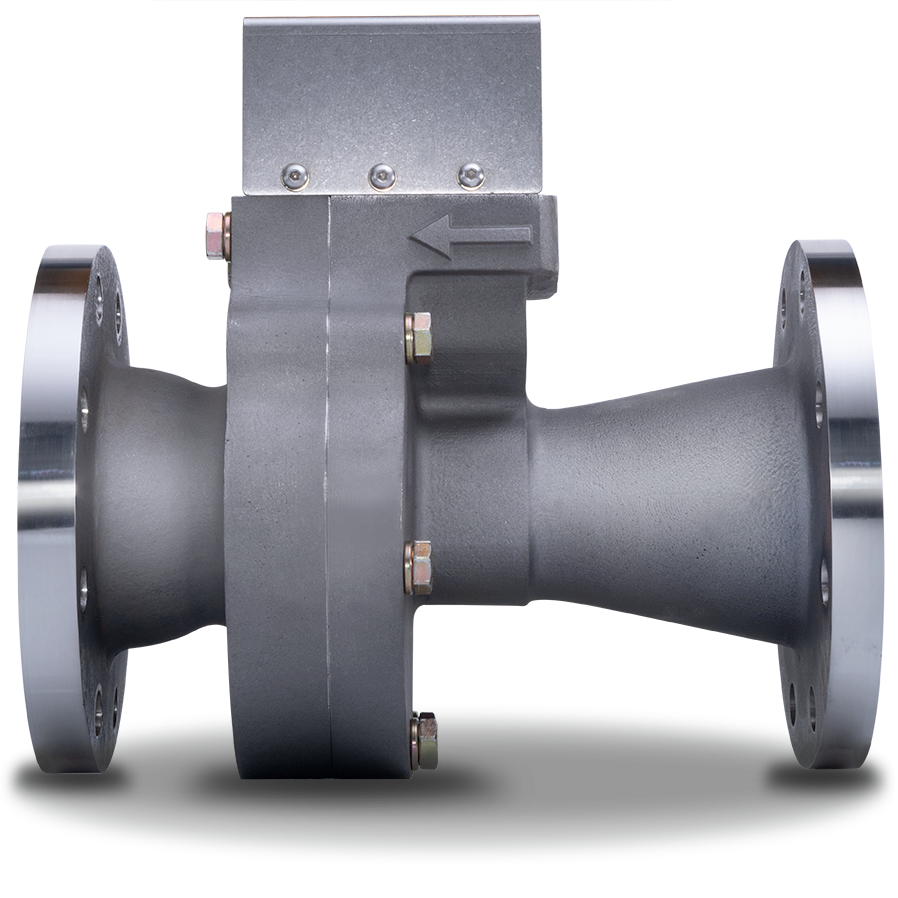

EFFICIENT FLOW PATH

The fluid is continuously in the centerline of pipeline, improving resistance to cavitation damage and lower noise. Curved closure members allow predictable pressure drops and provide a tight shut off.

Available CLass VI

Optional Class VI shut off up to ASME Pressure Class 1500 means zero leakage, with precise throttling capability that is easily programmed into the control system.

Designed For Safety

Shell and leakage tested in keeping with required industry standards per customer requirements before shipping.

Precision Rangeability

Centralized flow stream, from a fine mist to full port creates a high rangeability of up to 500:1, provides precise control that exceeds other globe control valve products.

Incredibly Compact Design

Smaller envelope and less weight compared to equivalent size control valves, while maintaining the ideal equal percentage valve characteristic. All of this is made possible by our patented mechanical design.

Small Actuators

Our closure members open and close perpendicular to the flow, thus reducing the required torque of our valve. That means you can go electric where you couldn’t before, and valve automation costs are significantly reduced.

Versatile

Standard materials are Carbon Steel and Stainless Steel, with other materials available, to suit your individual needs.

LESS = MORE

4″ Clarke Valve Dilating Disk™ Valve compared to a 4″ Globe Valve

Our Dilating Disk™ Valve is up to 80% lighter than traditional globe valves. Not only does this translate to ease of transport, assembly and installation, it also means a smaller carbon footprint. That’s because our valve’s use up to 1/3 less steel than legacy globe valves.

Our fully compliant, patented rotary stem allows for 98% less emissions than rising stem legacy globe valves. Less emissions, means less of a carbon footprint. And the drastic reduction in EPA fines means less overall operating costs as well! It’s a win for the environment and a win for your organization’s bottom line.

Dilating Disk™ Valves require significantly less maintenance than traditional globe valves. There are no tools required, no need for 3rd party lapping service, and they can be same day serviced on site to reduce downtime. We also have cost-effective spare part kits available which contain all the necessary parts to complete service intervals. Servicing your valve usually take less than 30 minutes once it has been removed from the pipe.

The unique design of the Dilating Disk™ Valve offers unmatched reliability. We use a patented sealing design to minimize exposure to process fluids, and our rotary stem simplifies the use of reliable, rotary actuators through a proprietary low torque design. The centralized flowpath virtually eliminates common problems found in other valves, such as cavitation and erosion damage. The Clarke Valve Dilating Disk™ Valve is proven, trustworthy and reliable.

Configure Your Own

Dilating Disk™ Valve Today!

NEWS + UPDATES

Kyle Daniels, CEO and Founder, Clarke Valve and inventor of the Dilating Disk™ Valve gives an insight into the technological shift and transition of valves manufacturing which is designed to regulate emissions and provide efficient processes in the oil & gas…

As operators in the oil & gas industry, it is vitally important to optimize the performance of control valves to maximize efficiency and profitability while maintaining safety and reliability. Usually, during a turnaround or maintenance, control valves need to be…

As 2022 winds to a close, it’s time for a look back at some of the most promising startups and the entrepreneurs leading them in Rhode Island over the past year. At Rhode Island Inno we covered a wide array…

Clarke Valve Location

DISTRIBUTOR

RESELLER

![]()

Clarke Valve Distributors Near you