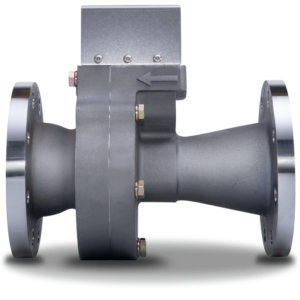

Winterizing your valves is key for keeping your operations running smoothly. When you take the time to prepare and maintain your valves and actuators, you’re reducing the risk of unwanted downtime which can lead to a loss in profits. Our Dilating Disk™ Valve product line was specifically engineered to withstand the elements, but with some additional precautions, you’ll be able to lock in a successful winter season for your organization with the world’s most compact and efficient control valve.

Actuator Pressure Drops

Safety and reliability are core factors for any organization that utilizes control valves within their operation. Whenever there is an opportunity to increase the reliability of the products you’re using, it should always be seized. As winter approaches and temperatures drop, it’s important that the pressure of your valve’s actuators is checked on a regular basis. Lower temperatures can lead to pressure drops, which, in some cases, can affect a valve’s ability to maintain its shutoff capabilities.

With the Dilating Disk™ Valve, you’re provided with a next-generation control valve that achieves Class IV shutoff with minimal torque. If the pressure within the actuators attached to your Dilating Disk™ Valves is not checked, it can compromise a valve’s ability to maintain those shutoff times and can increase the time of the actuator’s rapid response to control signals.

Ice Formation and Removal

Depending on the location of your organization’s facility, winter can mean exposing your equipment to unwanted snow, ice, and sleet. When ice forms on the valves and pipelines of your facility, movement issues can occur if the ice settles on, or around, valve stems. If the movement of the valve stem is compromised, the precision of the valve’s flow control capabilities may not be able to achieve the results your operation requires. To avoid buildup on your valves, end users and operators should always be checking for ice formations and making it a point to remove them periodically during the winter season. When checking the valve, it is also recommended to scout the area surrounding your valves for ice, since condensation can sometimes form on valve bodies and freeze when the temperatures dip to, or below, freezing.

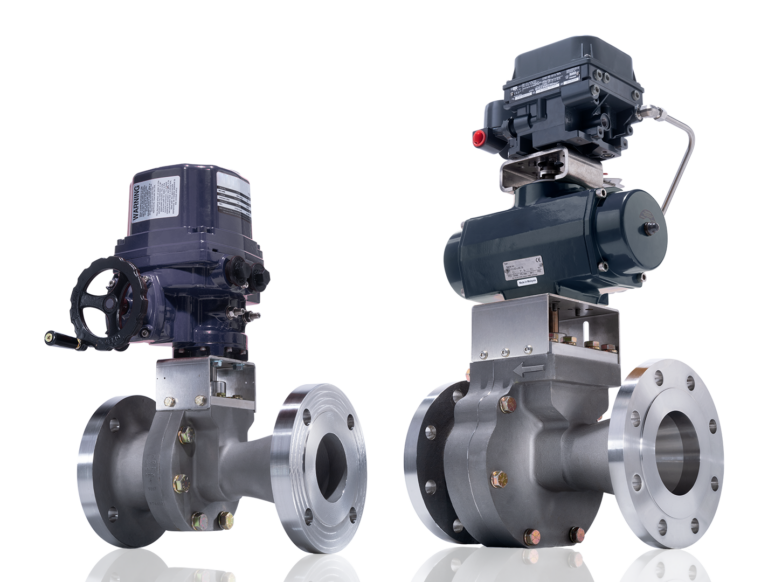

Pneumatic Actuators

Control valves with pneumatic actuation packages utilize instrument air pressure to apply the force needed in order to position the valve stem. Come wintertime, it is critical to verify that the instrument air to all actuators in your facility is dry. Any moisture that may build up has the potential to freeze, which can result in faulty operational incidents. Your valve’s actuators, supply lines, and filters need to be dry as well, so we always encourage a blowdown of these components to ensure that all unwanted moisture is removed.

Electric Actuators

For those who have made the transition to zero emissions with electric automation on their Dilating Disk™ Valves, be sure to check that the compartment heaters on your actuators are functioning properly. As previously mentioned, condensation can lead to unwanted ice formations on, and around, your control valves. If your actuator’s compartment heaters are not working as intended, you run the risk of condensation building up and freezing, which can negatively affect the actuator’s performance. All conduit seals should be inspected on a recurring basis throughout the duration of the winter as well. If there are any defects in the sealing mechanisms, water can seep into and damage the electrical components of your actuators.

The Dilating Disk Valve Difference

Any time we receive an inquiry for a Dilating Disk™ Valve order, many conversations and environmental conditions are taken into consideration and discussed between the customer and engineering team at Clarke Valve. This allows us to make sure that each valve we manufacture is designed to endure the application elements, as well as any inclement weather that the valve may be subjected to. Even though your Dilating Disk™ Valves do not necessarily need to be winterized, we still encourage end users and operators to take these precautionary steps. The Dilating Disk™ Valve’s ability to withstand inclement conditions, combined with its ultra-precise flow control, class IV shutoff, and zero emissions capabilities make it the top choice for a wide variety of applications during the cold weather season.