Clarke Valve, developer and manufacturer of the world’s most compact and efficient control valve, announced today that it has secured European Patent Office (EPO) protection for its proprietary Dilating Disk™ Valve technology.

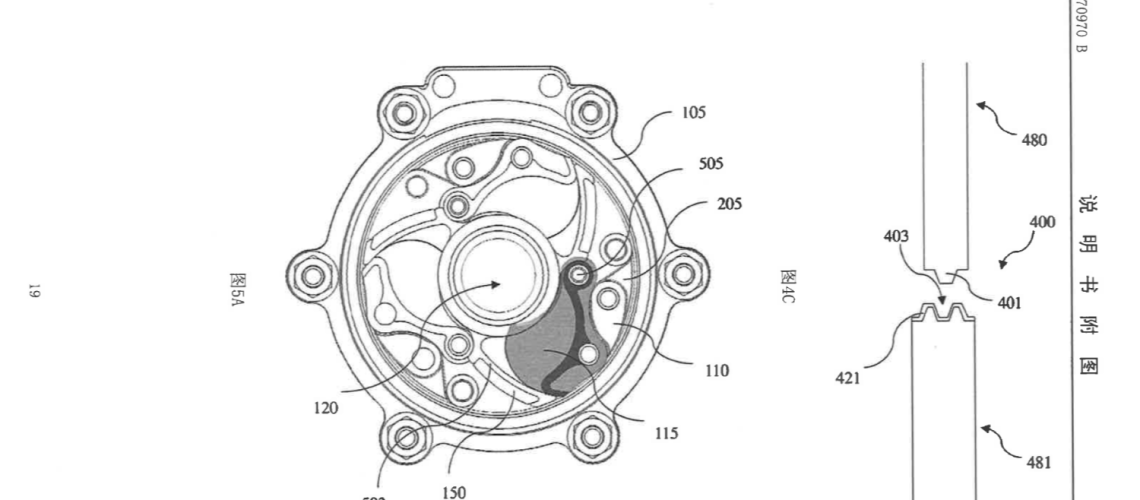

The Dilating Disk™ Valve represents the first major departure in control valve design of the past 50-plus years, employing a valve mechanism unlike anything found in commonly adopted models, such as globe valves and other valve types. The EPO granted patent number EP2988044 – “SHUTTER VALVE WITH PIVOT ARMS” in recognition of this differentiation in design achieved by Clarke Valve.

The Dilating Disk™ Valve uses three interlocking petals, mounted to a ring gear by pivot arms, to deliver precision throttling with minimal cavitation and zero pressure drop. The Dilating Disk™ Valve’s aperture creates a centralized flow stream, ranging from a fine mist to a wide-open port, resulting in certified 500:1 rangeability.

“Clarke Valve has engaged with a number of major oil and gas producers in the European Union, and we are continuing to establish relationships with distribution partners throughout the continent,” said Kyle Daniels, President and CEO. “We are pleased to add this European Patent to the patents we hold in the US, Japan, and elsewhere, and look forward to expanding our installed base in the EU.”

The unique bonnet and stem design of the Dilating Disk™ Valve also enabled it to become the first control valve to earn the American Petroleum Institute (API) 641 Certification, by virtue of its near elimination of fugitive methane emissions. The Dilating Disk™ Valve reduces methane emissions by more than 95% when compared to “low emissions” globe valves. This capability helped Clarke Valve to secure a capital infusion from OGCI Climate Investments, and has accelerated adoption of the Dilating Disk™ Valve in the oil and gas industry.

About Clarke Valve

Founded in 2011, Clarke Valve provides high quality industrial control valves to organizations worldwide. Using aerospace design principles, Clarke has developed the patented Dilating Disk™ Valve, meeting the ASME B16.34, ASME B16.10 and ASME B16.5 international valve standards, as well as ISO 5211 standards for valve automation. Due to its best-in-class sealing system, the Dilating Disk™ Valve is the first control valve to achieve both API 641 and ISO 15848-1:2015 certifications, making it the world’s most compact, efficient, and environmentally friendly control valve. Clarke Valve technology can be easily scaled or customized to meet many challenging requirements, and is currently deployed in a diverse spectrum of markets, including oil and gas, aerospace, chemical, power plants, and water management. All Clarke Valves are 100% inspected and tested to FCI 70-2 standards for control valves. Clarke Valve is an OSHA-certified ISO 9001:2015 company with a rigid Quality Control process that places an emphasis on the safety of our products.

For media inquiries, please contact Jason Alberti, Marketing Director, at jason.alberti@clarkevalve.com.