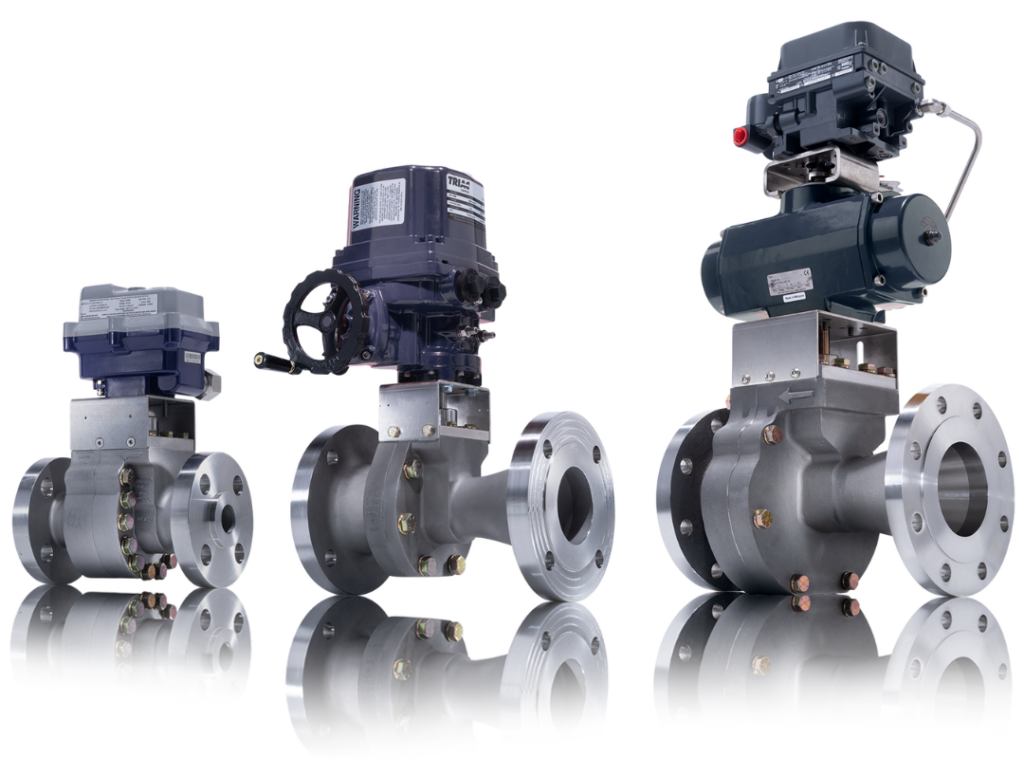

Next Generation Precision Control Valves

a product of evolution and enhancement within industry standards.

Our Dilating Disk™ Valve is up to 80% lighter than traditional globe valves. Not only does this translate to ease of transport, assembly and installation, it also means a smaller carbon footprint. That’s because our valve’s use up to 1/3 less steel than legacy globe valves.

Our fully compliant, patented rotary stem allows for 98% less emissions than rising stem legacy globe valves. Less emissions, means less of a carbon footprint. And the drastic reduction in EPA fines means less overall operating costs as well! It’s a win for the environment and a win for your organization’s bottom line.

Dilating Disk™ Valves require significantly less maintenance than traditional globe valves. There are no tools required, no need for 3rd party lapping service, and they can be same day serviced on site to reduce downtime. We also have cost-effective spare part kits available which contain all the necessary parts to complete service intervals. Servicing your valve usually take less than 30 minutes once it has been removed from the pipe.

The unique design of the Dilating Disk™ Valve offers unmatched reliability. We use a patented sealing design to minimize exposure to process fluids, and our rotary stem simplifies the use of reliable, rotary actuators through a proprietary low torque design. The centralized flowpath virtually eliminates common problems found in other valves, such as cavitation and erosion damage. The Clarke Valve Dilating Disk™ Valve is proven, trustworthy and reliable.

About Clarke Valve’s

Dilating Disk Valve

A completely reimagined, precision control valve that is light years ahead of any other globe valve on the market today. With unparalleled expertise in efficient flow pathways and mechanical design, Clarke Valve has established itself as the premier manufacturer of the next generation of precision control valves. The Dilating Disk series of valves deliver unparalleled efficiency and adaptability, putting them in a class of their own when it comes to efficiency, size, reliability, and sustainability.

Virtually Eliminate Fugitive Emissions with Clarke Valve

98% FEWER Emissions Than Traditional Globe Valves

Previously, near-zero leakage in an operating valve has only ever been achievable with a bellows seal, which can be very costly and complex to maneuver when maintenance is required. Clarke Valve records a methane leakage rate of only 2 parts-per-million (PPM)under the ISO 15848-1 Fugitive Emissions standard, compared to around 500 ppm recorded in conventional globe valves.

The Dilating Disk Valve Difference

With unparalleled expertise in efficient flow pathways and mechanical design, Clarke Valve has established itself as the premier manufacturer of the next generation of precision control valves. With a customer base consisting of over 35 of the leading oil and gas companies in the world, Clarke Valve provides easy-installation valves that help our customers meet environmental standards without paying a premium price.