Clarke Valve can get you to zero

and solve all of your methane venting & emissions problems

The EPA has just announced a sweeping set of domestic policies to cut emissions of methane from oil and gas operations across the United States.

New regulations will require all new and existing controllers to have zero emissions by 2023. Fines will start at $900 per ton in 2023 and increase to $1,500 per ton by 2025. We’re here to make sure you won’t have to pay a penny in fines!

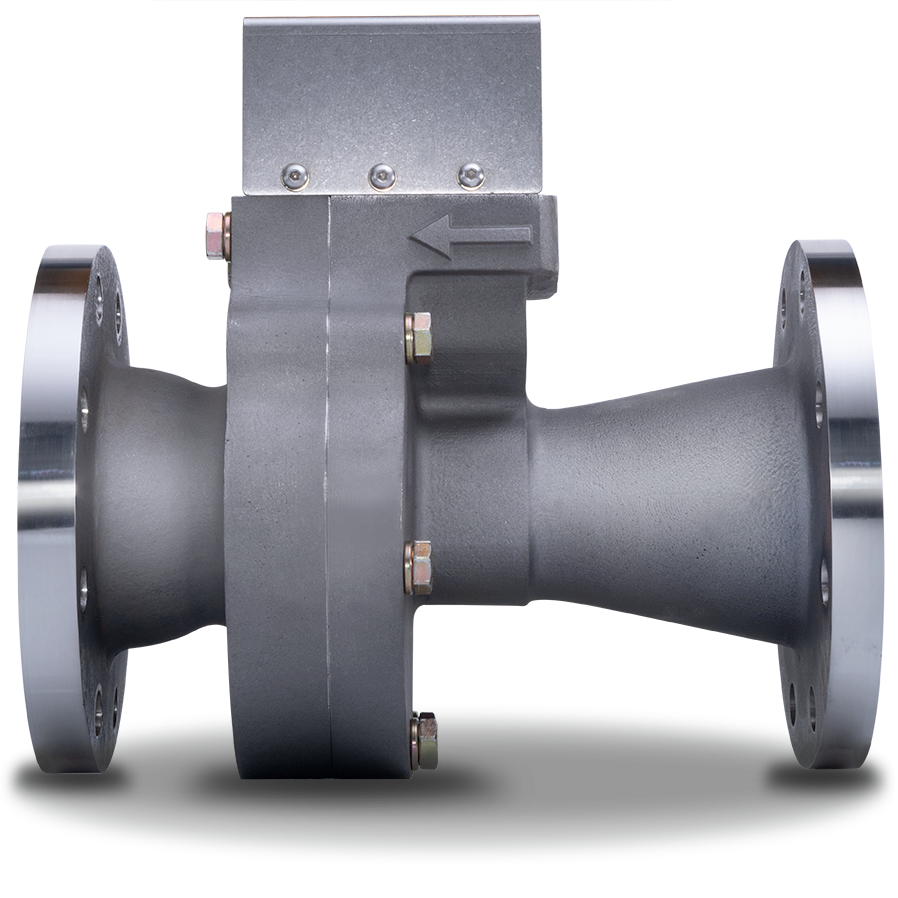

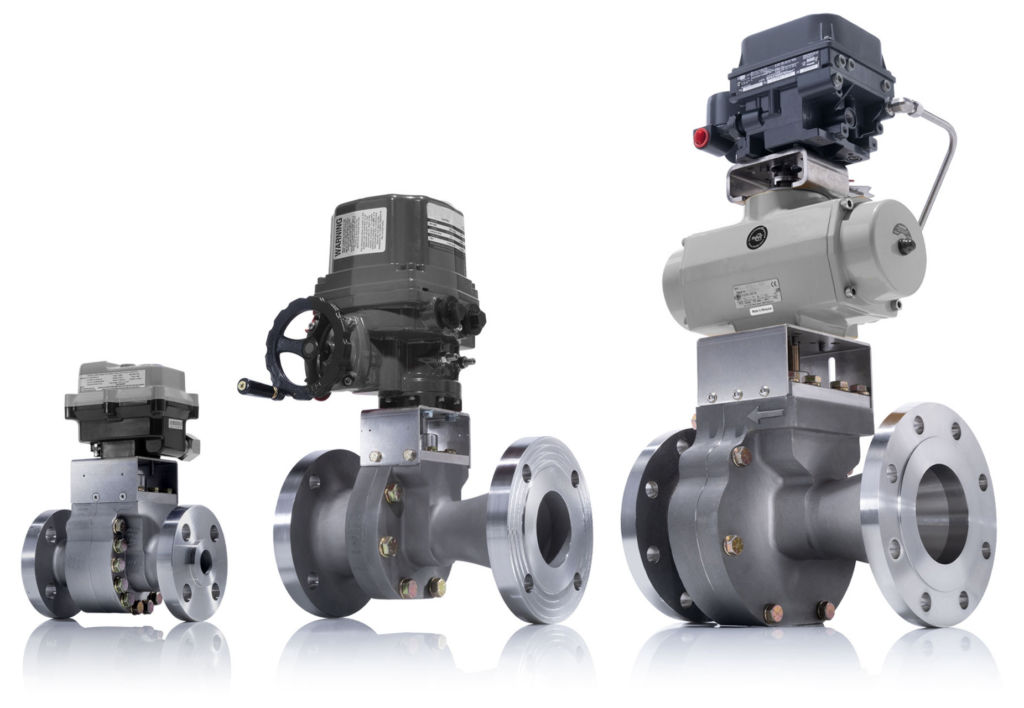

Clarke Valve's fully compliant Dilating Disk Valve is the only globe valve-equivalent, precision control valve that meets the zero emissions requirement. Reducing EPA fines means less overall operating costs! Better performance, lower cost of ownership and no fines, it’s a win-win for your organization’s bottom line.

The Time To Act Is Now!

Get ahead of global supply chain challenges. We're urging all of our customers to coordinate their project planning with their dedicated account managers before the EPA compliance deadline.

Contact us today to get started on the path to zero!

CONNECT WITH YOUR

DEDICATED ACCOUNT MANAGER

Clarke Valve Dilating DISK™ VALVEs proudly conform or maintain certifications to these respected industry standards.

- ISO 9001:2015 – Quality Management Systems – Requirements

- PED 2014/68/EU Annex III, Module H Certificate, CE0036

- Canadian Registration Number – ABSA CRN (Alberta) ACI CRN (NB, NL, NS, PE, NT, NU, YT), TSSA CRN Approval (Ontario)

- SIL 3 Certification – IEC 61508:2010 Parts 1-7, CLA 2005077 C001

- ISO 15848-1 – Industrial Valves – Measurement, test and qualification procedures for fugitive emissions – Part 1: Classification system and qualification procedures for type testing valves

- ISO 15848-2 – Industrial Valves – Measurement, test and qualification procedures for fugitive emissions – Part 2: Production acceptance test of valves

- API 641 – Type Testing of Quarter-turn Valves for Fugitive Emissions

- NACE MR0175 / ISO 15156-1 – Petroleum and natural gas industries – Materials for use in H2S containing environments in oil and gas production

- ANSI / NACE MR0103 / ISO 17945:2015 – Petroleum, petrochemical and natural gas industries – Metallic materials resistant to sulfide stress cracking in corrosive petroleum refining environments

- ASME B16.34 – Valves – Flanged, Threaded, and Welded

- ASME B16.5 – Pipe Flanges and Flanged Fittings

- ASME B16.10 – Face-to-Face and End-to-End Dimensions of Valves

- ANSI/FCI 70-2 – Control Valve Seat Leakage

- ISA-75.05.01-2000 Control Valve Terminology, Globe Valve

- API 6A – Specification for Wellhead Tree Equipment

- API 607 – Fire Test for Quarter Turn Valves Equipped with Nonmetallic Seats, External Leakage

- API 598 – Valve Inspection and Testing

- ANSI/ISA-75.02.01-2008 – Control Valve Capacity Test Procedure

- ANSI/ISA-75.17 – Control Valve Aerodynamic Noise Prediction

- ANSI/ISA-75.01.01 – Flow Equations for Sizing Control Valves

- IEC 60534-1 Part 1: Control Valve Terminology and General Considerations

- IEC 60534-2-1 – Flow Capacity – Sizing Equations for Fluid Flow Under Installed Conditions

- IEC 60534-2-3 – Flow Capacity – Test Procedures

- IEC 60534-2-4 – Flow Capacity – Inherent Flow Characteristics and Rangeability

- IEC 60534-7 – Control Valve Data Sheet

- IEC 60534-8-3 – Noise considerations – Control Valve Aerodynamic Noise Prediction Method

- IEC 60534-8-4 – Noise Considerations – Prediction of Noise Generated by Hydrodynamic Flow

- IEC 60534-9 Part 9: Test Procedure for Response Measurements from Step Inputs

- ISA-RP75.23 – Considerations for Evaluating Control Valve Cavitation

- BS EN 12266-1-2012 Industrial Valves – Testing of Metallic Valves – Pressure tests, test procedures and acceptance criteria – mandatory requirements

- ISA-75.05.01-2000 Control Valve Terminology

- ISA-75.08.01 – Face-to-face Dimensions for Integral Flanged Globe Style Control Valve Bodies (Classes 125, 150,250, 300, and 600)

- ISA-75.08.06 – Face-to-face Dimensions for Flanged Globe Style Control Valve Bodies (Classes 900,1500, 2500)

- ISA-75.11.01-1985 Inherent Flow Characteristic and Rangeability of Control Valves

- ISO 5211 – Industrial Valves – Part Turn Actuator Attachments

- MIL-DTL-32632 – Valves, Flow Control, Dilating Disk, for Naval Shipboard Water, Oil, and Gas Service

- MIL-V-24509A – Military Specification – Valves, Flanged, Ball and Plug for Sewage and Sea Water Service

- MIL-S-901D (NAVY) – Military Specification – Shock Tests (High Impact) Shipboard Machinery, Equipment, and Systems, Requirements For

- MIL-STD-167-1 (SHIPS) – Department of Defense Test Method – Mechanical Vibrations of Shipboard Equipment (TYPE 1 – Environmental and TYPE II – Internally Excited)

- MSS SP-55 – Quality Standard for Steel Castings for Valves, Flanges, Fittings, and Other Piping Components – Visual Method for Evaluation of Surface Irregularities

- MSS SP-61 – Pressure Testing of Steel Valves

- Hazardous Service – ExdllB T6, Class 1, Div 1, Group C&D T6

- QQ-N-281D – Federal Specification Nickel Copper Alloy Bar, Rod, Plate, Sheet, Strip, Wire, Forgings, and Structural and Special Shaped Sections